The contractors continue to work through the Remote Thermal Area punch list including

repairing sheet rock, cleaning up building penetrations, clean up material and reinstalling the roof gutter down spouts. We also have contractors out working on the balance of the in-line fans for the strip and wash duct and the K-hut duct.

We received another shipment of VIRUS Platforms/Ladders;

it contained the platform side supports for both VIRUS right and VIRUS left and a top work platform for one of the VIRUS enclosures. We have been doing test fits of these enclosures in preparation for installing all of them in two weeks.

John Good, mechanical engineer from Austin, was here for the last two weeks to work with the laser tracker. The first days were spent confirming the current mount model then making refinements to it. We now believe we have the best mount model that can be obtained with this laser tracker.

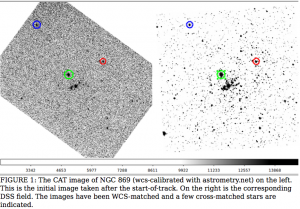

Some work at night was done this week. We went on sky to test the mount model, see if the position of the Celestron Alignment Telescope (CAT) was good enough for future testing. We found the RA, DEC and rho offsets are now working and that the center of rotation falls at the corner of the CAT. Tests of the geosynchronous satellite tracking software within TCS suggests that it is probably working although the CAT is just to small to see these 11-13th mag objects. We believe we are sufficiently ready for any future metrology tests. With this alignment out of the way we put the CCAS tower mirror alignment system back together and have confirmed that all of the components are well aligned and working with alignment to better than 0.5″.

Work in the spectrograph room continues. One of our TOs finished the touch-ups required after the contractors scratched the paint in the area where the HPF enclosure will go. With that done we are ready for the HPF enclosure to arrive next week. We also received the mounts for the HRS sensors. These will be part of the system that monitors and controls the HRS temperature to improve performance in velocity stability.

The really big news is that we installed the large liquid nitrogen tank behind the K-hut. This required days of preparation and coordination between the HET, Crane services, Praxair and Midwest Cryo teams. The two cranes made quick work of putting the crane in place and by lunch the tank was bolted down. In the two following days nearly all of the plumbing to the K-hut vaporizer and the filling location were installed.