This past two weeks have been eventful. Most of the prior week was spent trying to get the VIRUS enclosures and cryogenic safety systems online for the first delivery of liquid nitrogen into our big tank. This involved installing lots of cryogenic lines and one large LN2 tank on each of the VIRUS enclosures.

Although a few last minute alterations had to be made, the filling of the tank went smoothly. A single truck can not fill our tank but we did put in 4,000 gallons of LN2 into it. Much of this liquid would be burned off quickly to cool the tank and all of the cryogenic lines that lie between the tank and the VIRUS enclosures. Just for reference the cost of very pure LN2 trucked out to W. Texas is about a dollar a gallon.

The contractors for the tank and cryo-lines lead a safety class for the staff and we reviewed all of the alarm and oxygen sensors now placed around the facility.

The mirror team continues to swap freshly coated mirrors for the mirrors with the oldest coatings. This past week they swapped 4 mirrors.

We have installed an in-line filter for the fan venting the CCAS tower. This filter will allow us to reverse the fan and run it continuously during the day to keep the tower close to ambient temperature. The software group has finished a prototype piece of code that will turn off the fan just after sunset or if the weather conditions indicate a “close all domes” condition such as high humidity or dust.

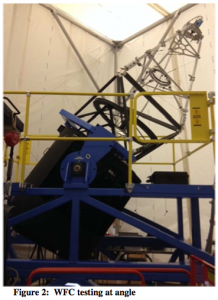

The wide field corrector is undergoing extensive “at angle” testing to make sure that the alignment can be maintained between the assembly and shipping vertical axis and the 55 degree angle that it will live at in the tracker. These tests are being done at University of Arizona. When done the corrector will be put into a special shipping box and sent to W. Texas on a special air-ride truck.