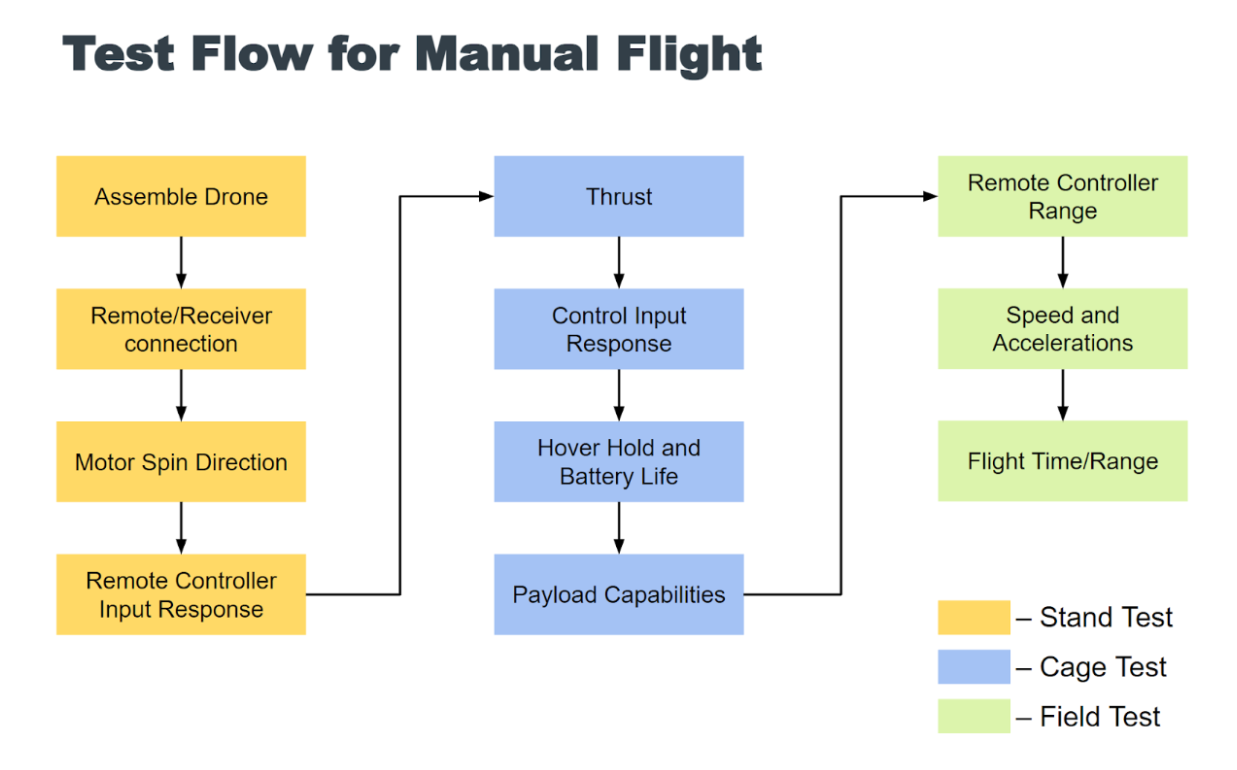

Our testing procedures are going to split into three test phases. The phases are named by the environment they must be conducted in. Currently we are at the DRONE CAGE PHASE:

- Test Stand Phase

- Transmitter to Receiver Connection

- Pixhawk Flight Controller Calibration

- Center of Gravity

- Motor Spin Direction

- Transmitter Control Input Response

- Object Detection

- Drone Cage Phase

- Thrust

- Control Input Response

- Hover

- Payload Capabilities

- Object Avoidance

- Field Phase

- Transmitter Range

- Flight Time

- Flight Range

- Speed and Accelerations

The test stand phase mainly consists of testing whether our hardware is operational. This includes testing motor functionality, transmitter to receiver connections, flight controller calibration, and a few more tests. Our drone cage phase will include such tests as monitoring thrust output, control input response, and object avoidance. The field phase will have tests regarding our transmitter range, flight time, and flight range.

These tests do not include test plans for sensors or autonomous flight, although those will need to be tested as well sometime in the future after manual flight has been achieved and sufficient data has been collected. Here is a diagram further outlining our test plans for the drone.

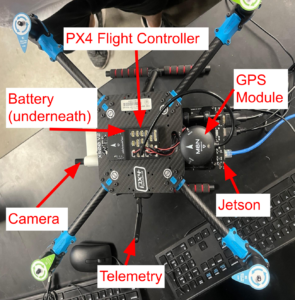

Drone Prototype 1 Hardware Overview

In the Fall 2023 semester, the hardware team was able to order 4 new, upgraded drones to supplement the single drone the team currently has. This will allow the team to gain experience installing new flight controllers, modules, and sensors onto the new drones and will give a wider array of sensors to utilize for estimation. Upgrades include the following:

- A flight controller with a pre-installed ESC (electronics speed controller, used to control motor speed) – the previous drone had a separate ESC, which required a soldered connection to the main flight controller, increasing the chance for electrical errors.

- GPS module – while the main mission of the lab is to achieve GPS-denied navigation, having a GPS module as a way to calibrate the estimation calculations will allow for more accurate analysis of our data.

- ZED camera – this powerful camera allows tracking in 6 degrees of freedom (3 position vectors, a 3 orientation quaternions), using the getPosition() command. The sl::pose: class also timestamps, confidence values and a rotation matrix with regarding to the world frame.

A diagram of the planned configuration of the new sensors on the new drone frame is shown below.

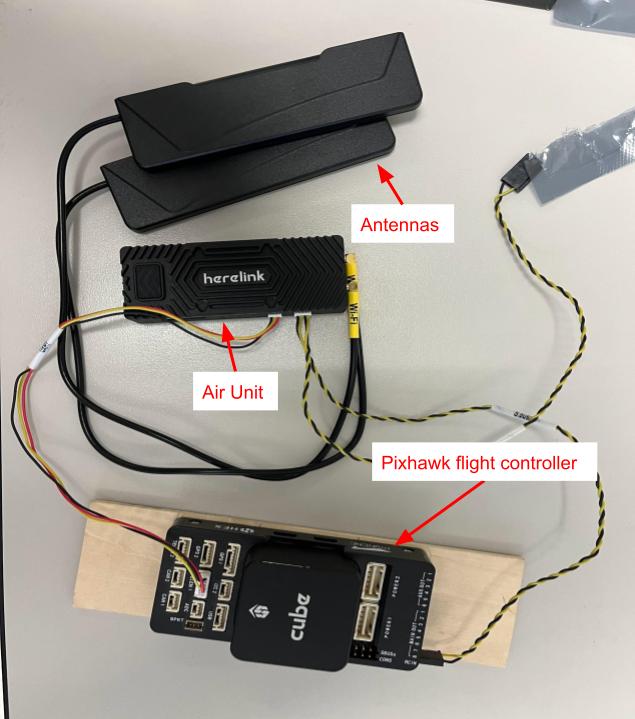

As of 12/4/2023, the team has the new pixhawk flight controller set up with the new air unit and antennas (shown below). Additionally, the Jetson flight computers have also arrived and the team will begin building the connectors to connect it to the pixhawk.

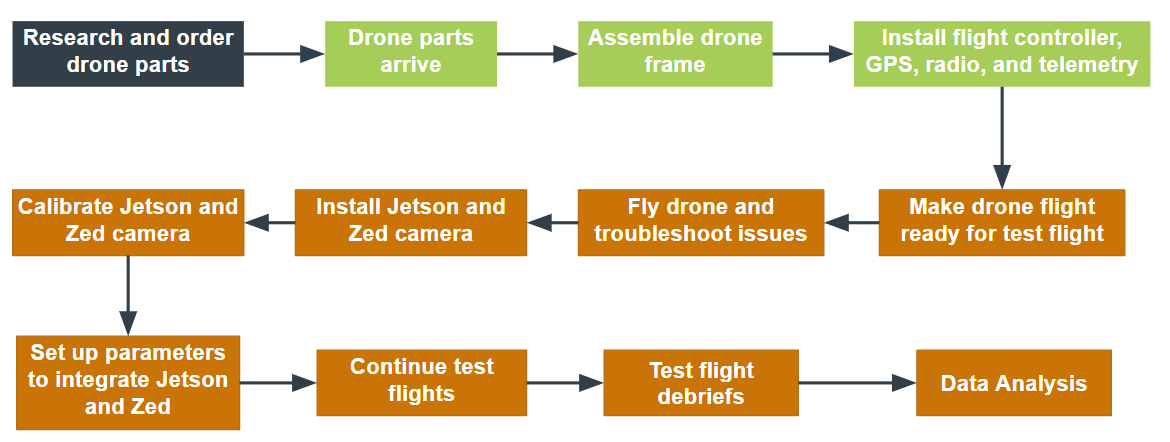

Next steps for the hardware team are as as follows:

- Assemble new drones with new flight controllers, GPS, radio, and telemetry systems.

- Conduct basic test flight to ensure reliability and trouble issues that arise.

- Install and calibrate Jetson and ZED camera.

- Conduct test flights with Jetson and ZED cameras installed and transfer data from the ZED camera to the estimation team.

- Continue test flights with estimation software installed onto the Jetson.

The process flowchart below depicts where the team is in terms of flight test readiness, updated as of 12/4/2023.

These steps will likely last well into the Spring 2024 semester, after which the team will have many options on what to pursue.

In addition to the custom-built drone frames, the team also acquired 2 DJI Mavic drones, which are commercial-off-the-shelf drones typically used for filming. The hardware team plans to attach the team’s IMU to the DJI drone to obtain preliminary data even before the custom drones are ready. Additionally, flying these drones will give the team flight experience and allow for more stable data collection (since these drones are designed to get static shots). A picture of the drones is shown below.

(image credit: DJI)

Laboratory Operations Equipment

Laptops: Dell Precision 7780 Workstations

We recently completed the procurement of two powerful laptops that will help finish our research. The devices are future-proof and provide enough technology to power extensions of our research into visual-inertial-based motion planning with advanced sensors and swarm systems. Ground station laptops are key during real operations for providing EKF and data visualization computation. During testing SITL simulations will be completed on said laptops.

(image credit: Dell)

3D printer: Raise3d Pro3 Plus

Also procured is a carbon fiber-capable 3D printer from Raise3D. Although DEL has purchased off-the-shelf airframes recently, these items usually require significant modification to accommodate sensors and for general structural performance. Thus, an advanced 3D printer will allow the team to easily build key physical components.

(image credit: Raise3d)

Mobile Power Station: Jackery Explorer 2000 Plus

DEL importantly completes flight testing within drone cages and has plans to test drones in open environments. To charge drone batteries and power laptops, a mobile power station will be used as all flight testing currently completed is away from a physical power supply.

(image credit: Jackery)

Storage Cases:

To store expensive and possibly hazardous equipment, DEL purchased two large, hard plastic cases. These cases will be locked for security and were chosen to provide some protection against the possibly hazardous electronic equipment needed for DEL operations like LiPo batteries. Cases will be key during remote flight tests where significant amounts of equipment will be taken to the field. Laptop bags were also purchased to hold the powerful laptops and their support equipment.