Fall 2023 – Spring 2024

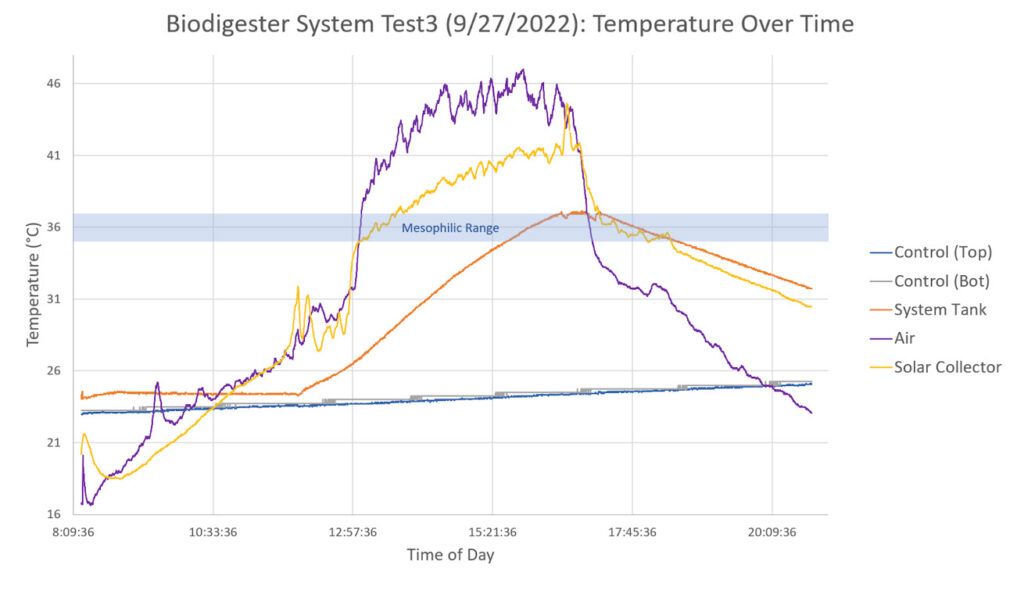

In order for anaerobic digestion to occur, the temperature of the vessel that holds the waste should fall within the optimal range for the bacteria doing the digesting. For anaerobic bacteria, this range is dubbed the “mesophilic range” and is around 30-40º C (Figure 2). Our group aimed for a range of 35-38ºC to target the most efficient conditions. Many commercial biodigesters use external heat sources, such as burning fuel or photovoltaics, to maintain the temperature within the optimal range, but those solutions are not always a possible application in areas with limited resources such as Cox’s Bazar. William Carter, senior officer at the International Federation of Red Cross and Red Crescent Societies (IFRC), suggested that this project design a cost and space-efficient method to achieve the optimal operating conditions for a Flexigester®, a commercial flexible biodigester utilized in Cox’s Bazar, and has provided guidance to the team throughout the semester.

Project Description:

Refugee camps around the world face numerous health issues due to the challenges of waste management. To face these challenges, the biodigester was developed to decompose waste using anaerobic bacteria. In order to accelerate the process, our system uses solar collectors, made of polyethylene pipes coiled onto a zinc backing, to heat water inside the biodigesters to a temperature range of 35-40 degrees Celsius. The goal of our project is to ensure that the temperature inside of the biodigester remains in this range for as long as possible to maximize waste digestion.

Eric, Faith, Anita, Sneha, and Alessandro working at Brackenridge Field Laboratory

Student Experiences:

“This class is super unique and fun since everything is really hands on and interactive! ”

-Sneha Sundar

“I like that I can work on a project that can have real world impact ”

-Anita Mishra

“I get to apply a lot of the things I learn in some of my classes”

-Eric Williams

“I really enjoy that we get to work with the same group for a long period of time”

-Alessandro Supriyatno

Prototyping:

Faith, Alessandro and Sneha setting up their new solar panel

Members of Team Biodigester pose after setting up their first test of the semester

Prototypes and Schematics:

Data Collection:

“This class is a great chance to bring together everything you’ve learned in your engineering courses and make something impactful.,”

– Eva Patel

“Seeing something that we’ve made work and be successful has been really rewarding!,”

– Lindsey Nguyen

“It was my favorite class this semester. I gained a lot of hands-on experience and learned a lot about what industry is like.,”

– Faith Leake

Student Caitlyn Harris working on building the new solar collector prototype.

Student Caitlyn Harris working on building the new solar collector prototype.

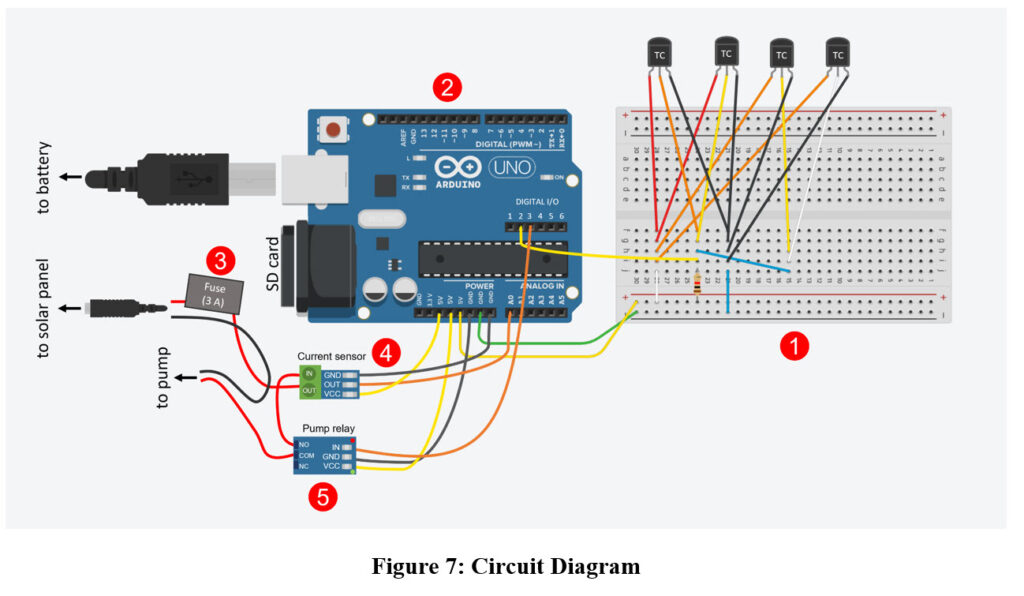

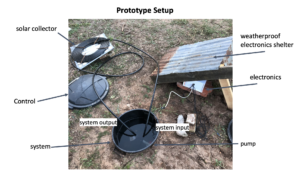

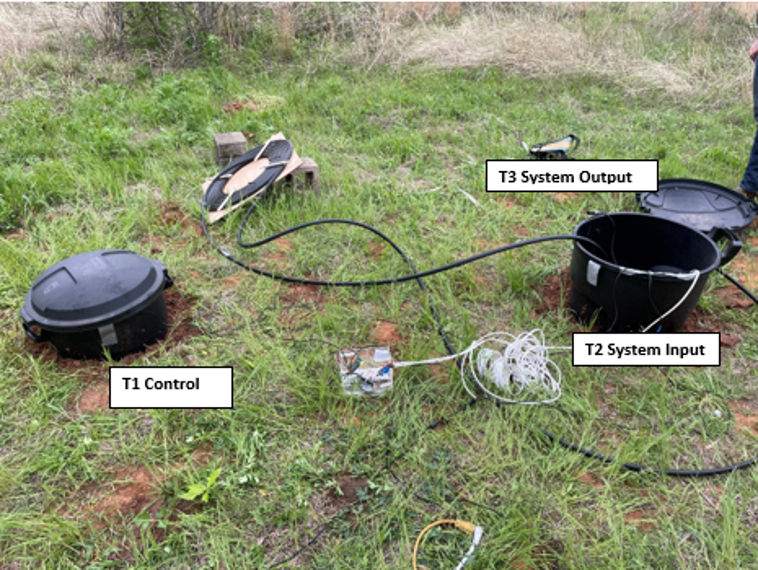

Experimental system setup showing the control trash can (left), the solar collector prototype (back) oriented at optimal angle, system trash can (right) simulating a biodigester, and the Arduino system (middle) equipped with temperature sensors measuring temperature change.

Experimental system setup showing the control trash can (left), the solar collector prototype (back) oriented at optimal angle, system trash can (right) simulating a biodigester, and the Arduino system (middle) equipped with temperature sensors measuring temperature change.

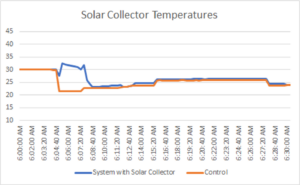

Graph representing proof of concept by plotting temperature data in Celsius over time of our system (blue), control (red), along with the ambient temperature (yellow). This displays our system maintaining the required temperature range of 30 to 40 degrees Celsius for six hours.