Fall 2023 – Spring 2024

Project Description:

Team Pad is developing a machine to make menstrual pads onsite in refugee camps, providing employment and menstrual hygiene products to refugees. The basis of this report will be to inform others of our progression and the technical process of our prototype.

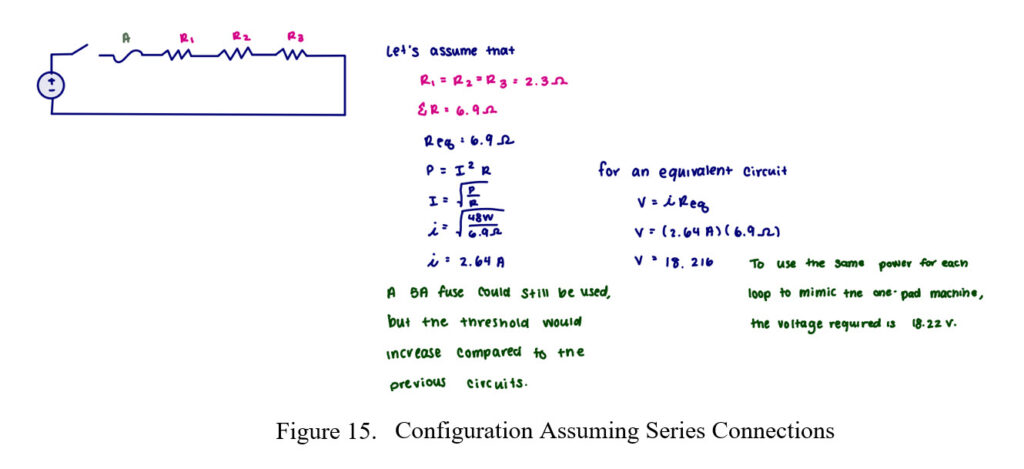

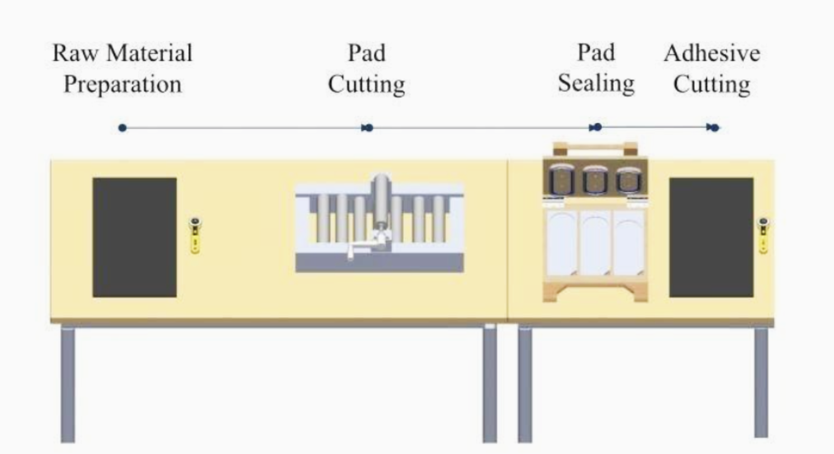

Team Pad, alongside the International Federation of the Red Cross and the members of the Humanitarian Engineering Advisory Panel at UT, have developed and iterated upon a prototype of mechanical and electrical systems that produce pads as based on our criteria for success. The prototype consists of a set of die cutters and the 3-pad machine itself, which is a power supply connected to 3 kanthal wires in loops that heat to the desired temperature. Our design is built upon a 1-pad prototype built by previous teams. The materials are first cut using a die cutter, then selected layers are sealed together using the 3-pad machine.

Student Experiences:

“HPD gave me some great hands-on experience!,”

-Nora Agah

“HPD and the Pad Machine project gave me experience with both design and prototyping, as well as skills related to fundraising and leadership. ”

-Anastasia B. Timoshenko

“I loved getting to work on a project that has a real impact.”

-Hannah Weiner

“HPD has exposed me to problem-solving and product development on a real and impactful project!”

-Amy Yang

Criteria for Acceptance:

- Production consistency at 100%

- Low cost per pad

- 120 pads per hour

- No need for manual touch-ups

- Consistent temperature maintained throughout circuit

- Acceptable size; fits in a medium-size suitcase

“It was extremely rewarding to work in an interdisciplinary team of other engineers and see our progress throughout the year. Through this project, we were able to experience in engineering areas such as project management and product design.”

– Shelby Gammon

“My experience on Team Pad helped me learn so much more about the trial and error process that goes into carrying out a long-term prototyping project. Working on a student team and applying real-life engineering to help women in refugee camps across the world was an extremely rewarding opportunity.”

– Ashwini Prabhu

“It feels really good being able to apply what we’ve been learning for the past few years while knowing we are making a direct positive impact on people’s lives.”

– Grace Young

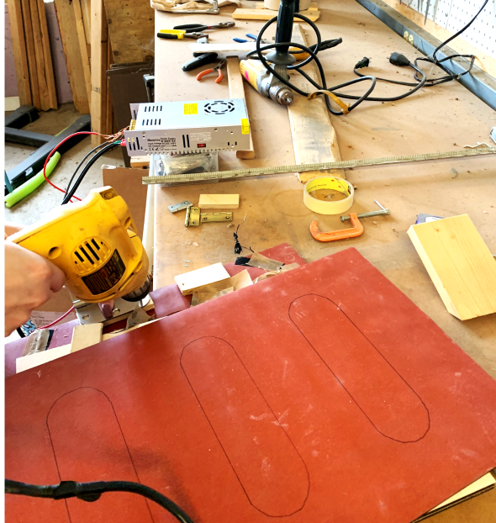

Grace Young drills holes in order to add hinges to the pad press prototype.

Theoretical Setup of Prototype in a Working Environment.