I participated in an introductory course to research in engineering in my second semester at UT (Spring 2021). Three other undergraduates and I were paired with a graduate student in the Nanoscale Design and Manufacturing lab – David Cayll who himself was supervision by professor Michael Cullinan.

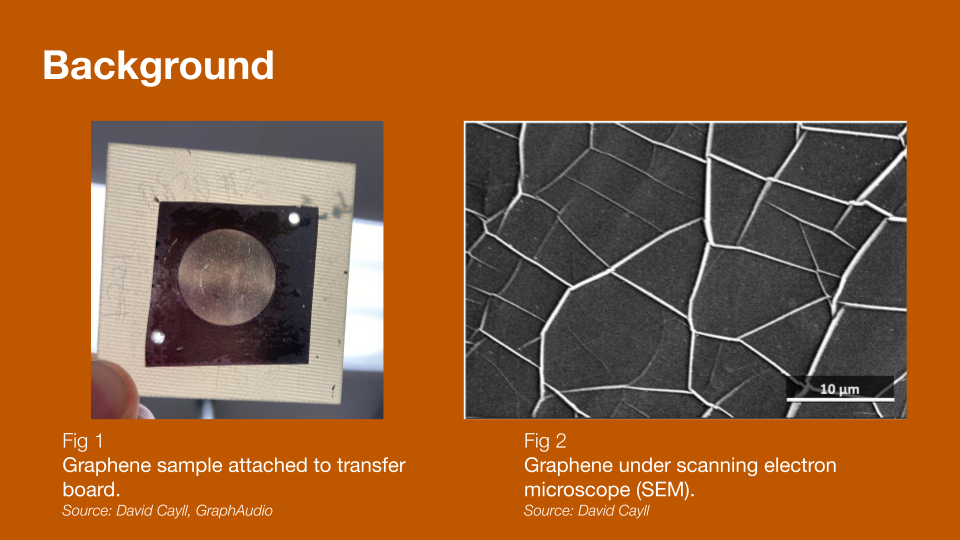

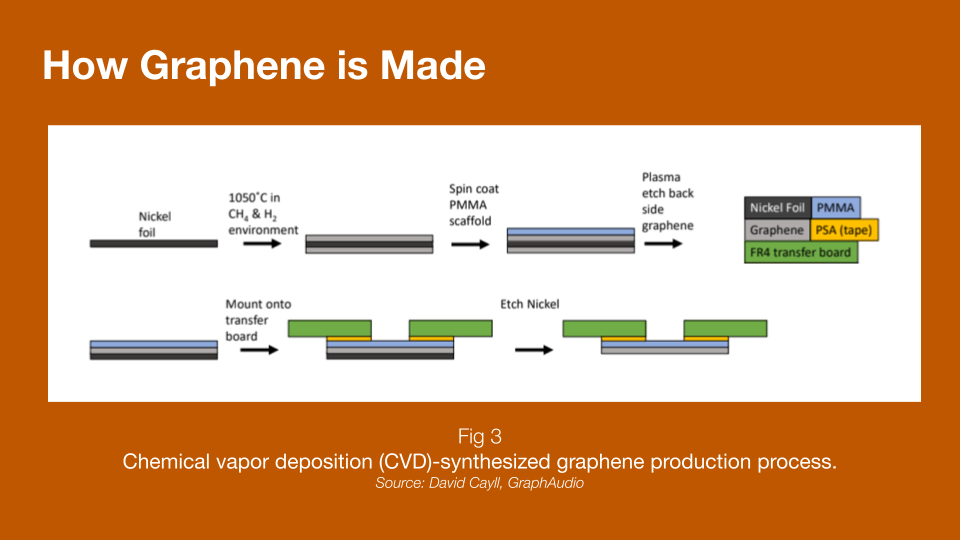

The engineering challenge he posed towards us was to design an experiment and the necessary equipment to estimate the elastic modulus of thin graphene samples produced through chemical vapor deposition. David’s end goal was to implement these multilayer graphene layers as diaphragms for transducers in speakers and microphones. Due to their extreme thinness, these graphene sheets required support materials for any movement.

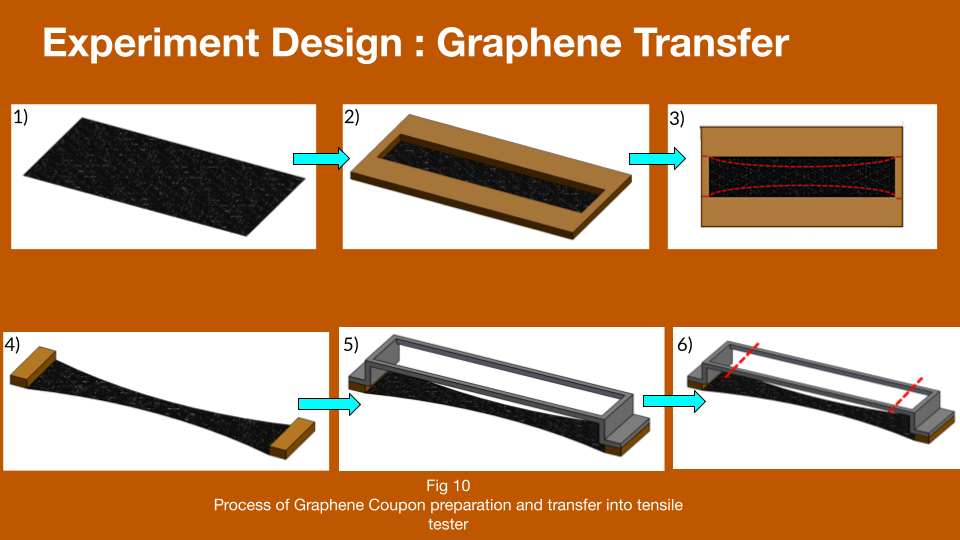

To address the issue of sample preparation and transfer, we proposed the following process.

- Adhering the raw graphene to an FR4 transfer board with a slit, and transferring the entire assembly to a laser cutter or other cutting tool. (step 2 in diagram)

- Cutting of the entire assembly, shaping the specimen to a dogbone while leaving some transfer material intact on the ends. (steps 3 & 4 in diagram)

- Adhering a “bridge” made from PLA or other easy-to-cut plastic to the remaining transfer material and transferring this assembly to the tensile tester. (step 5 in diagram)

- The cutting of the wire-like “suspenders” of the bridge using wire cutters or other simple cutting tool. (step 6 in diagram)

My group presented all of our work and learning at the end of the semester and won the third place award.

This project was my first serious venture into mechanics and material testing, but I learned so much and have continued to investigate the subject in later projects.