According to the official document of the negative photoresist SU8-3005, we know there are two methods to remove the SU8 PR. (1.) PR Remover immersion (2.) Dry-etch using SF6.

When I preparing the Al2O3 mask for the DSE, I find the difference between the two methods, so this post is to record the difference.

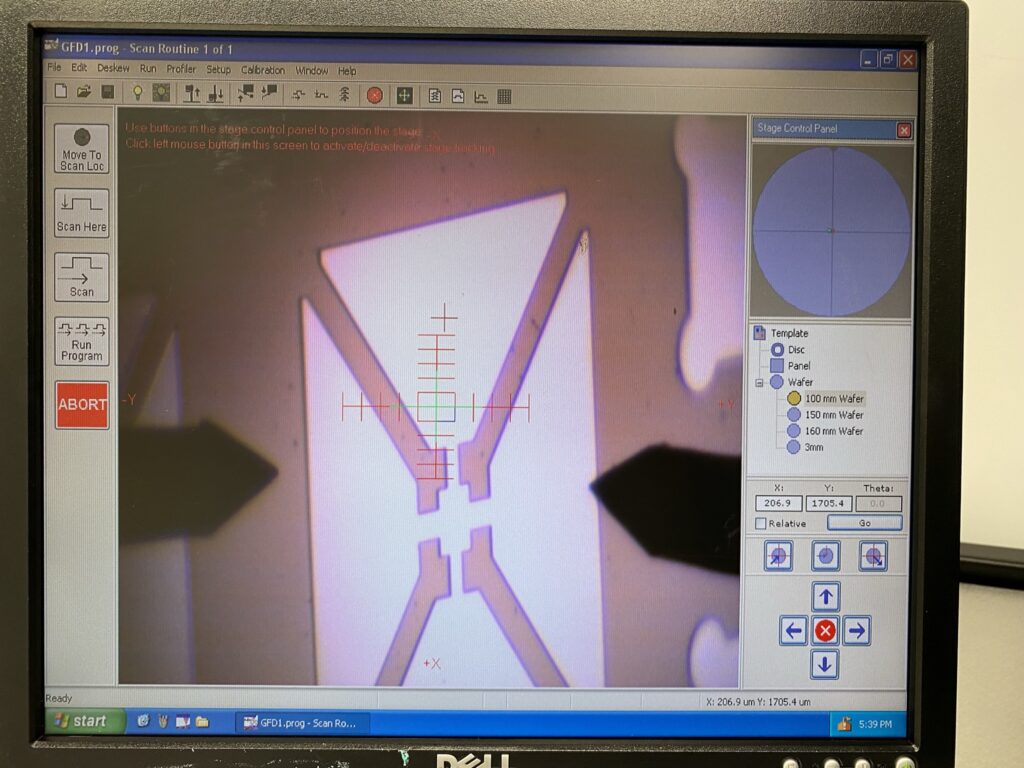

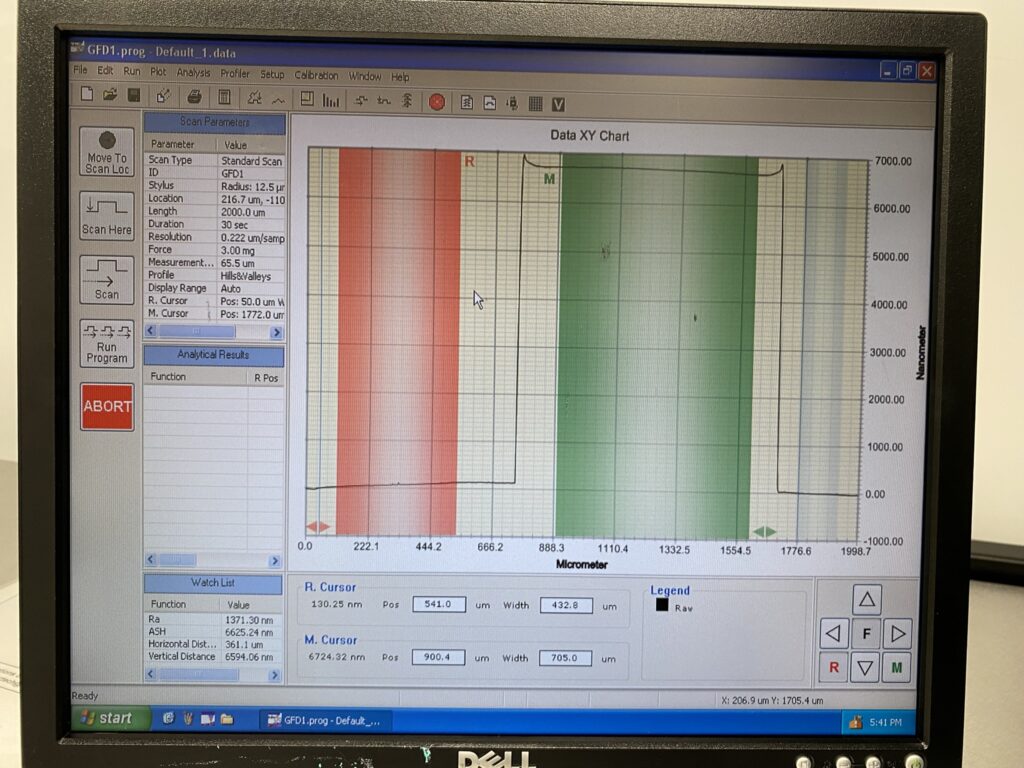

1.Al2O3 Dry-etch: Oxford ICP RIE 100

| SU8 PR |

| Al2O3 |

| Silicon |

The step made of SU8 and Al2O3 is higher than the flat made of silicon by 6.594 um.

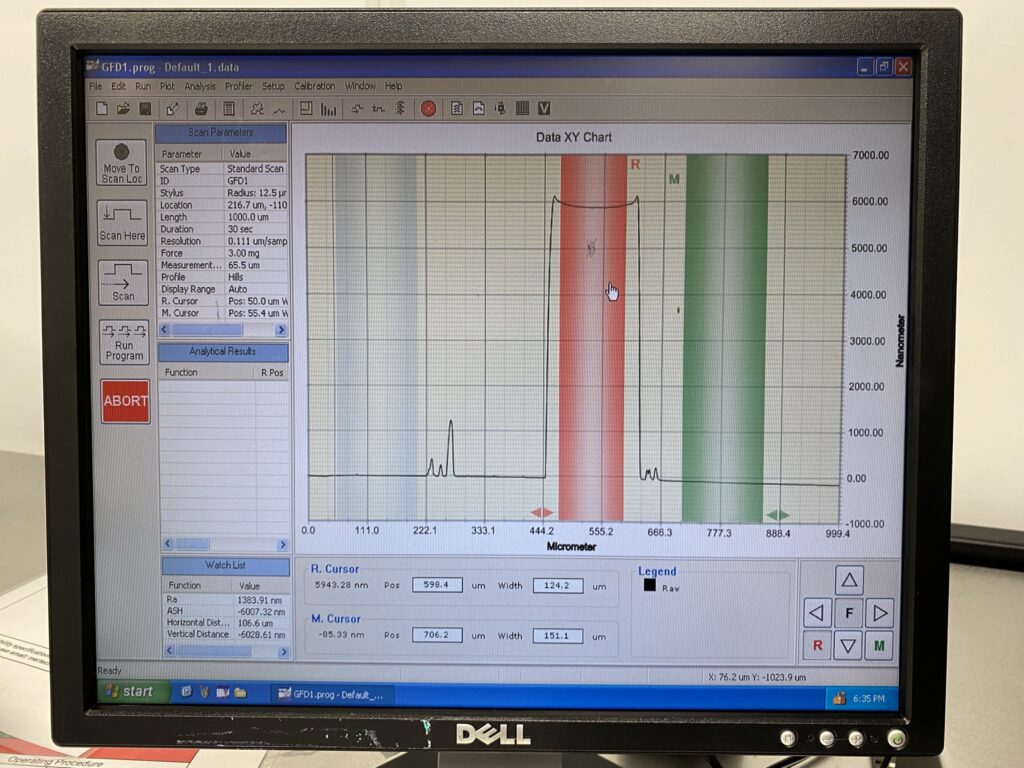

2.Dry-etch SU8 using Oxford 80

The step made of SU8 and Al2O3 is higher than the flat made of silicon by 6.028 um.

The SU8 PR is about 7 um. The result shows that the PR hasn’t been cleaned up.

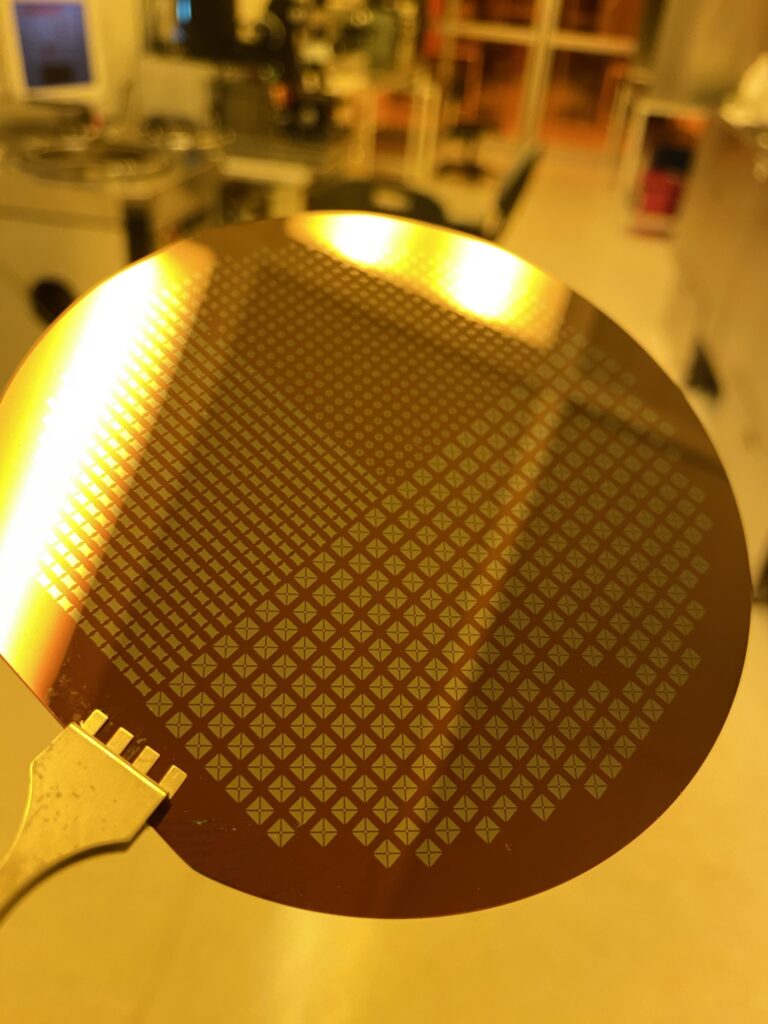

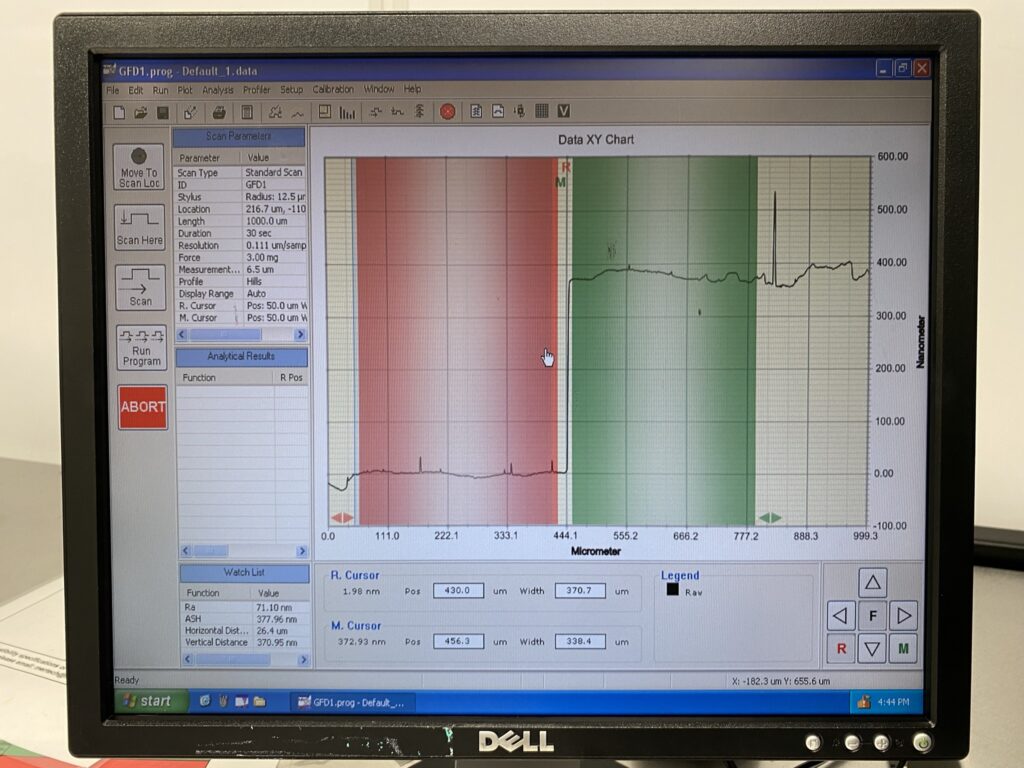

3.Use PR Remover to lift off the SU8 PR

The highland made of Al2O3 is higher than the flat by 370 nm. However, we already know the thickness of Al2O3 layer is about 240 nm.

The silicon is etched during the SU8 PR is dry-etching.

Conclusion

If there is no pattern on our wafer, the dry-etch is fine to remove the SU8 PR; otherwise, the dry-etch would damage the pattern on the wafer.