Rheology of soft particle pastes

Contact: Lavanya Mohan (lavanya.mohan@utexas.edu)

Soft particle pastes like microgels and compressed emulsions are densely packed, disordered suspensions of soft and deformable particles. In these the soft particles are jammed, and they behave like weak elastic solids at rest and low stresses but flow like liquids above the yield stress. This unique feature makes them useful as rheological additives to process high-performance coatings, ceramic pastes, drilling muds, textured food and personal care products. A quantitative bridging of the microscopic parameters, microstructural changes and macroscopic properties would enable customized design of the fluid.

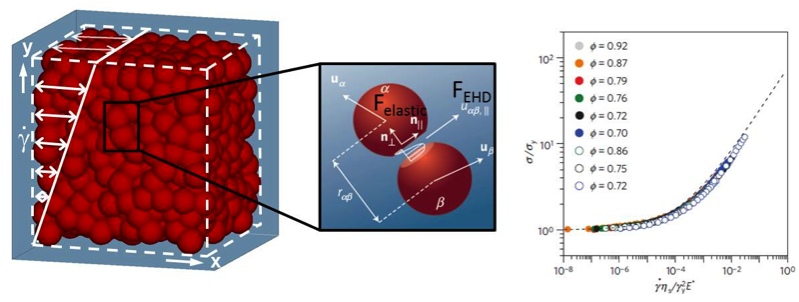

Left: Simulation box for soft jammed glasses. Center: Particle contact interactions. Right: Simulation predictions for the flow curve (line) and comparison to experiments (symbols)

My research is about creating tools to understand and design these materials. We have developed micromechanical 3D simulations and built the microstructural analysis to quantitatively predict their nonlinear rheology during steady shear [1]. Large Amplitude Oscillatory Shear (LAOS) is a widely used characterization technique for these complex fluids and we have built particle scale simulations to predict their macroscopic properties and determined the underlying microscopic changes that give rise to their macroscopic oscillatory rheology [2].

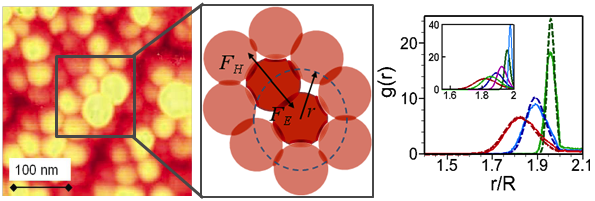

We have also developed a pairwise interaction theory to predict the pairwise distribution function and elastic properties of quiescent pastes. The short ranged pair distribution function was predicted using a transport equation that includes a concentration dependent mean force that captures the effect of the bulk suspension on the pair interaction [3]. I am currently working on extending the pairwise theory to predict the sheared microstructure and flow properties of these pastes.

Left: AFM image of a microgel paste. Center: Schematic representation of the forces used in the pairwise theory. Right: Theoretical predictions of pair distribution function (solid lines) and comparison to simulations (dashed lines)

Contact: Ben Huntington (bhuntington2716@gmail.com)

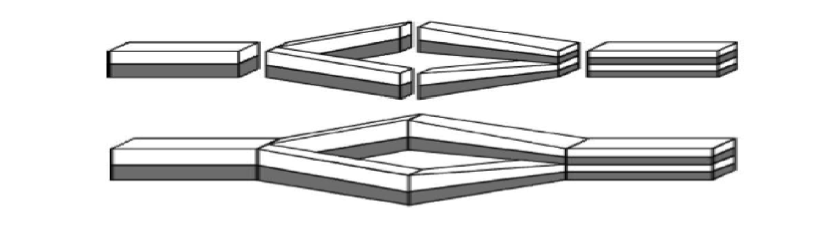

Micro and nano-layered polymer composite materials have a variety of different applications. Very finely layered polymer materials have a large range of technological applications, including optical data storage, lenses, organic lasers, gas barriers, and water purification membranes. All of these applications either require or are greatly enhanced by having flat layers that have controllable thicknesses. These materials are made via a special coextrusion process at Case Western Reserve University that takes an input of a small number of layers (2-8 layers) and then, by splitting and recombining the flow repeatedly, creates a very finely layered material. The multiplying process is depicted in the figure below.

A multiplier die splits a two layer flow of different polymers and then stacks the flows to create a four layer flow. Figure from Dooley, J.: Viscoelastic Flow Effects in Multilayer Polymer Coextrusion. Ph.D. Thesis, Eindhoven University of Technology (2002).

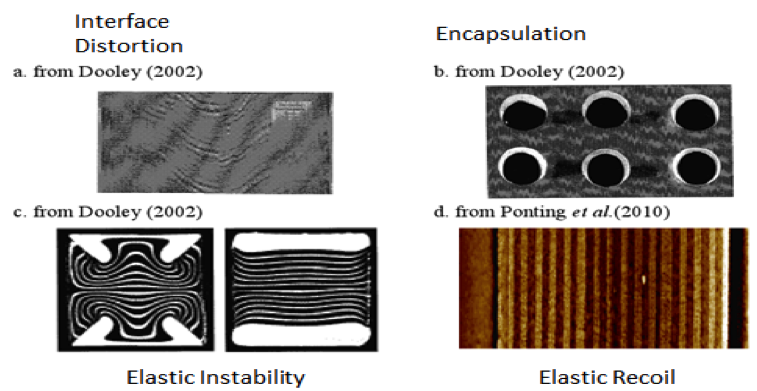

This process creates many distortions in the layers of fluid, often resulting in the destruction of the layered structure. These flows can be related to the viscous and elastic forces that exist in polymer flows. In flows where the viscosities and/or elasticities are very different, the distortion in the layers can become so extreme that one of the fluids encapsulates one or more of the others, resulting in a material that no longer has the desired properties. These defects and instabilities are seen in Figure 2. The goal of my research is to determine the causes of this distortion and determine ways to negate or circumvent it. My work uses theoretical and computational tools to simulate these flows and their distortions. It serves to augment and guide experimental work being done at Case Western Reserve University.

A variety of different interface distortion mechanisms are shown. Figure from Simulation and Analysis of Multiphase and Stability of Coextruded Layered Polymeric Films M.S. Thesis, Chabert, E., University of Texas at Austin (2011)

Contact: Mohammadreza Shafiei (shafieimo@gmail.com)

Fractures and leakage paths lead to reduced oil recovery during production from hydrocarbon reservoirs. Waterflood can not sweep oil from low permeability zones which contain unswept oil. Polymer microgels can minimize this issue during flooding process by blocking high-permeability zones, specially fractures and diverting waterflood to low permeability zones. These polymers can swell several times as pH increases. At low pH, the viscosity of polymer’s solution is low so it can be placed deeply into the high permeability zones of reservoirs. As a result of reaction between polymer and rock minerals or cement(behind pipe) within reservoirs, the polymer viscosity increases so water flood could be diverted from high permeability zones to low permeability zones. To measure rheological properties of polymer solution, laboratory experiments is conducted. The properties like yield stress, viscosity are measured for different polymer concentrations and for different salinity as a function of pH. For the next step,a mathematical model is developed to predict the behavior of pH-sensitive polymer. The model is applied at the reservoir to verify the leakage issue.