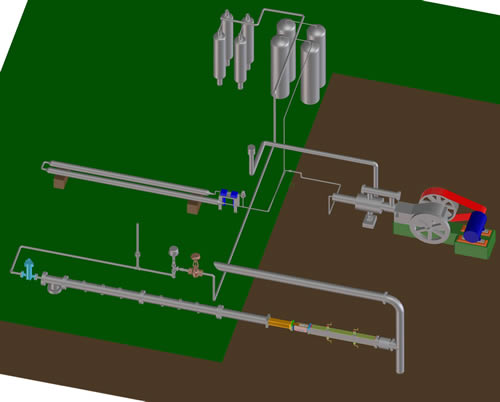

The high-speed wind tunnel facility can be operated at either Mach 2 or 5 — the Mach number is determined based on the nozzle block that is used. The tunnel is of the blowdown type and operates for run times of 1 to 2 minutes, depending on the conditions. The test section at Mach 5 is 6″ wide by 7″ high, whereas at Mach 2 it is 6″ high by 6″ wide. Windows in all four walls provide optical access for laser diagnostics and schlieren. High-pressure air is provided using a Worthington air compressor and 180 ft^3 tank farm with working pressure of 2000 psi.

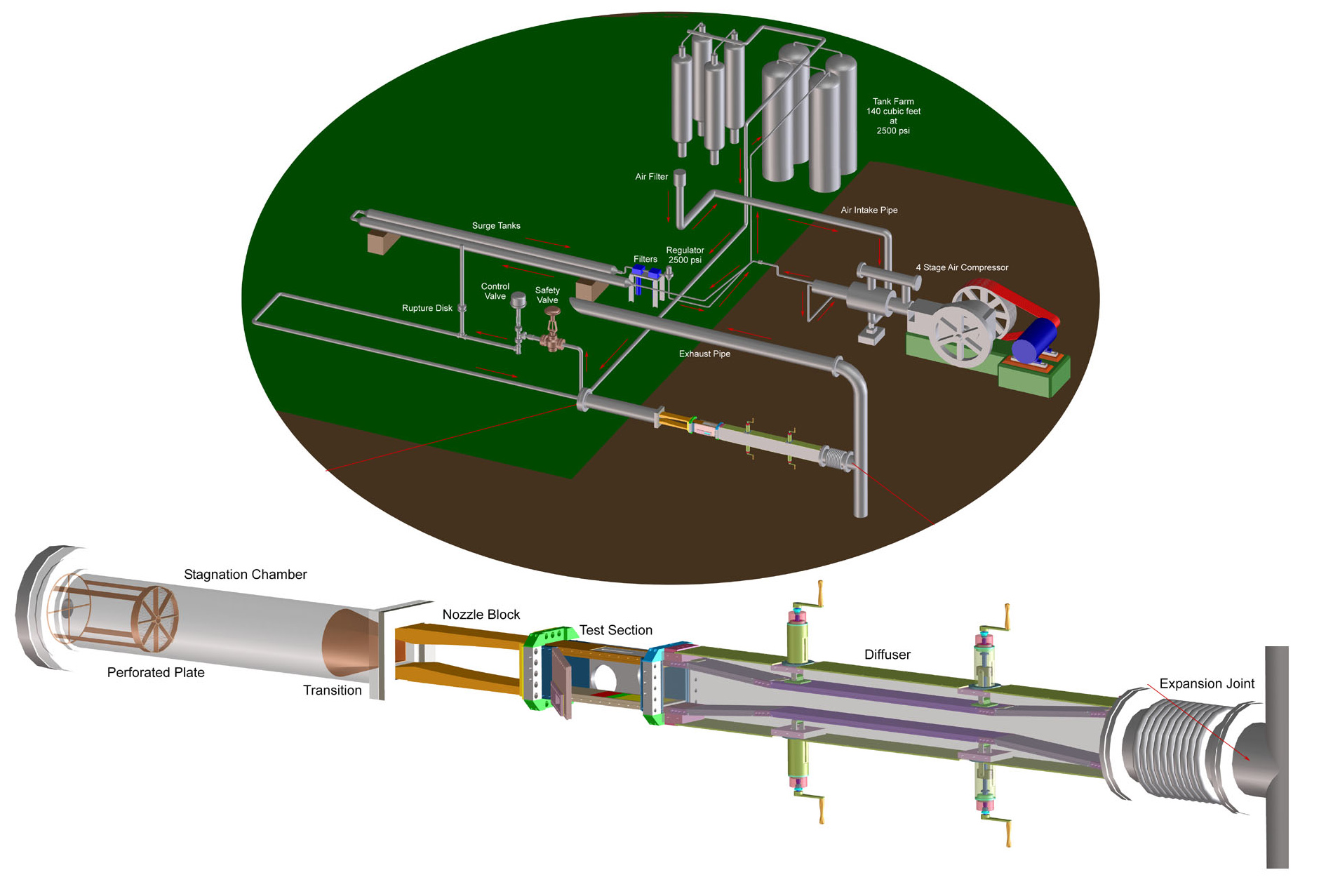

This facility has been used for decades to study a wide range of flows including supersonic boundary layers, shock wave/boundary layer interactions, flow-structure interaction, low-temperature ablative flows, cavity flows and missile aerodynamics. Diagnostics that are routinely used in the facility include fast-response pressure transducers, schlieren, particle image velocimetry (at rates up to 100 kHz), pressure sensitive paint, digital image correlation and laser-induced fluorescence. The figure below shows the the tank farm that supplies the high pressure air, the test section with cameras configured for PIV, and a sting-mounted model in the test section. The stagnation pressure and temperature are approximately 25 atm and 350 K, respectively, which gives typical unity Reynolds numbers of about 30 million per meter. Run times are typically one minute, which gives sufficient time for converged statistical data to be collected.

(a)

(b)

(c)

Mach 5 Wind Tunnel (a) high-pressure air-supply system and wind tunnel cross-section; (b) test section with PIV setup; (c) open test section with missile on a sting-mounted force balance.