As mentioned in the previous post in the week of December 8 many of the staff were working off the facility. This week most everyone is back on site.

The team who went to Texas A&M had a very busy week. They soldered glycol lines, installed covers and tested the system under pressure. They found some leaking at 40 psi and at 80 psi the leaks were severe. The team left it back in the hands of the A&M engineers for them to fix these severe problems. The 2nd VIRUS enclosure is supposed to go on the telescope in January and at that time we would like to do an end to end test of the chilled glycol system.

The team who went to Germany for the HET board of directors meeting brought back good news. The board was pleased to see the progress that the operations team is making and authorized the use of some operations funds for the wide field upgrade to make sure that the teams in Austin and West Texas have enough personnel to stay on schedule for a summer time first light. They were also impressed with the latest installation video, the nitrogen tank installation. Please have a look at: https://www.youtube.com/watch?feature=player_embedded&v=2a1xZF1b0wQ.

The groups that were not traveling have been busy as well. The work on the Anemometer project has drawn to a close. We are collecting data. The next step is to start visualizing the data and actually trying some experiments with louver positions with respect to wind and dome position. This will be a longer term effort.

The night staff have been optimizing the stacks and are now able to get stacks of less than 0.5″. The software team worked this last week to set those optimizations as the default in the stacking code.

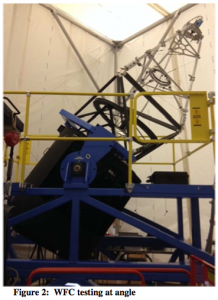

An engineer from Austin came out this past week to begin the installation of a clean room for the much anticipated WFU corrector. This huge 4 glass Spherical Aberration corrector will be brought in from University of Arizona on a special truck that will minimize vibration. Even so, when it does arrive it will have to be tested to see if it is still in alignment. This will be done in a clean room tent we are constructing in our loading bay. This will take up the majority of the loading bay for a month and will stop us from receiving any large shipments for the dome floor. This week the frame for the tent went in.

Even over the holiday break we will continue to get some work done. The contractors working on the remote thermal area will be receiving and installing the glycol chiller on site on December 30th. The system probably will not be fully ready to go until mid-January when the 2nd VIRUS enclosure is installed.