Since last week included a holiday we will include activities from the last two weeks.

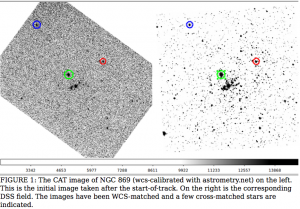

This week we had a software engineer from Austin visiting to commission the Metrology loops in software. The includes the distance measuring interferometer, the tip-tilt sensor and guiding with the CAT. The team was able to accomplish all of these at a single azimuth but problems with the alignment of the CAT stopped further exploration of the performance of the system. We will test the alignment of the CAT on Sunday so that further commissioning can continue.

In the previous blog post we mention the discovery of some loose bolts. The source of the “loosening” is still a mystery but we installed an accelerometer to look for significant jarring events on the tracker. This week we took it down and looked at the data. The most serious events were those of the installation and removal. Even forced Emergency Stops did not produce large accelerations.

Commissioning of the Strip and Wash Room continues. The room heater and make-up air were tested and found to work but needs small tweaking with regards to the indicator lights on the controls. Other members of the team are working on the Safety Protocols document. They believe that commissioning will be completed by January 5th and that we should resume mirror swaps in the primary at that time.

This week one large project has been completed. Phase I of the Dome Sealing and Conditioning was completed with the last of the dome “hair” seals being refurbished. With the completion of Phase I we have sealed the vents on the ring wall, refurbished the seals at the base of the dome, sealed the leaky dome nodes and replaced all of the louver seals. We note that this last rainy season we did not have any leaks in those locations. Phase II involves sealing the dome shutter and will require some engineering.

The technical teams at the HET continue to make progress on various projects such as continuing installing the VCS Safety System components; installing a differential thermostat and a parallel temperature acquisition system in the K-Hut to monitor inside and outside temperatures over the weekend; and test fitting the PFIP Electric Box Frame Weldment Assembly. One pending item that was accomplished was to replace the structure drive wheels. These wheels were showing considerable wear and we replaced them before a failure could occur.

The Anemometer project has made some progress this week. All of the units were calibrated and the system was run over night on Wednesday and Thursday. Some problems were found in shared memory flags in the database but these were cleared up and we should be able to start collecting data and looking at how to best visualize and utilize this new data set to minimize dome seeing induced by turbulence.

In the coming week we will be down a large number of staff. Three of the operations team who are traveling to Texas A&M to speed along the final assembly and testing of the 2nd VIRUS enclosure. Three other people from the operations team (including the blogger) will be traveling to Germany for the HET Board of Director’s Meeting. Much of the last two weeks was spent in preparing reports and presentations for this meeting.