Predictions of the Mass Transfer in Structured Packings Using Computational Fluid Dynamics

- Sponsors: Eastman Chemical Company, Linde

- Principal Investigator: Dr. Bruce Eldridge

- Graduate Research Assistant: Luke Macfarlan

- Status: Complete

Chemical separations are widely performed in industry, with vapor-liquid contactors often accomplishing these separations and providing high-purity products. Structured packings are commonly employed in vapor-liquid contactors and exhibit low pressure drops, high throughputs, and excellent chemical separation performance. Despite the widespread use of these packings, the transport phenomena occurring within them are incompletely understood, inhibiting improvement efforts. Computational fluid dynamics (CFD) is a promising approach to predict the transport phenomena occurring inside the packings and to guide packing innovation.

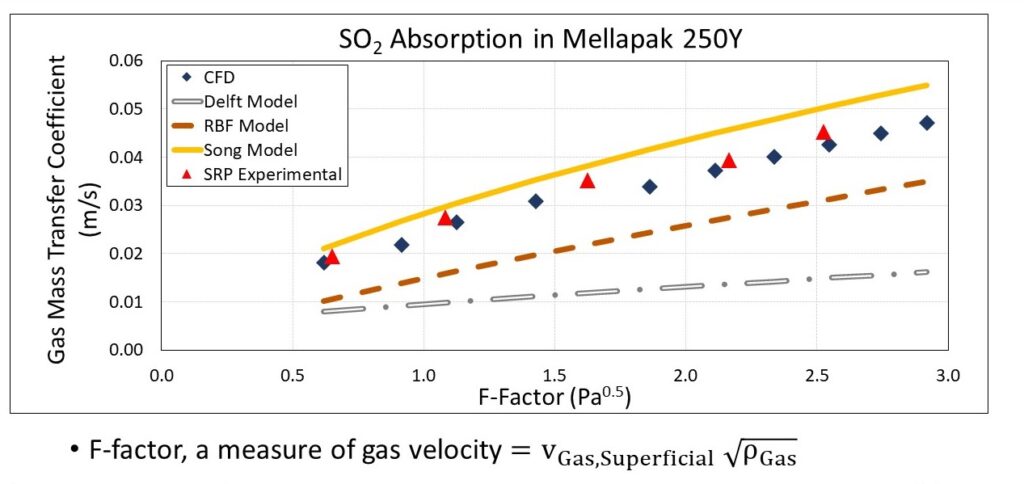

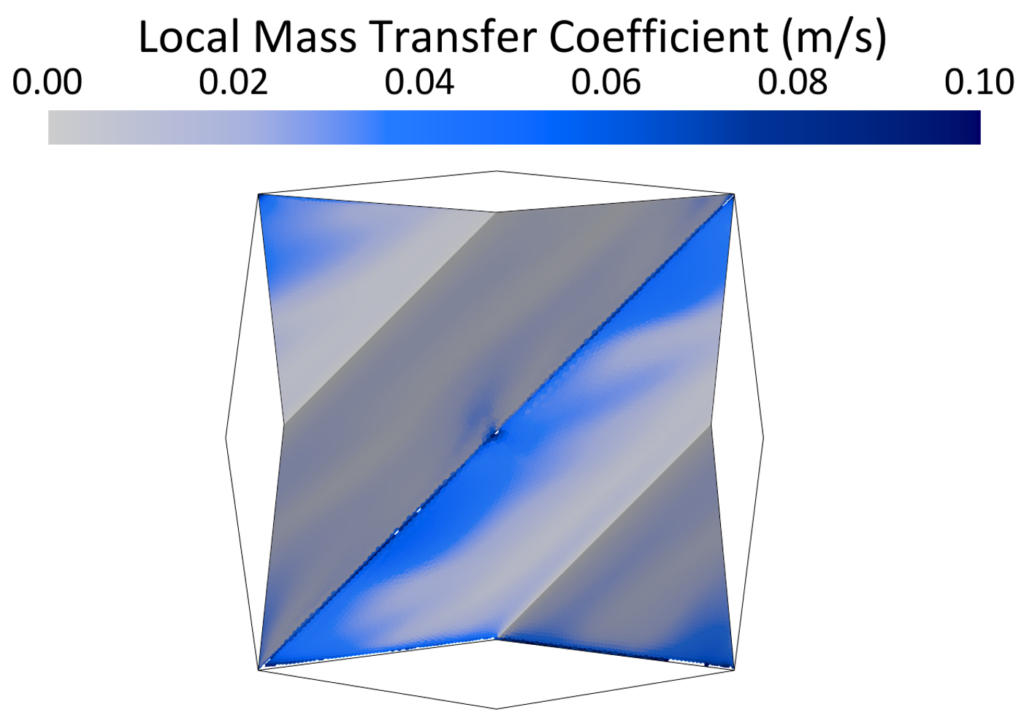

In this work, CFD predicted the gas-phase mass transfer performance of structured packings, and several key observations resulted. After a model for turbulence-aided mass transfer was identified with pipe flow simulations, the gas-phase mass transfer performance of a traditional structured packing was predicted. The mass transfer coefficients from CFD showed a five percent deviation compared to experimental data, validating the simulations. A geometry investigation determined the impact of three fundamental structured packing parameters on the packing performance. Improved mass transfer performance often occurred at the cost of hydrodynamic performance. Turbulence had a large impact on the gas-phase predictions.

The liquid-phase mass transfer in structured packings was also simulated. A novel simulation methodology enabled the structured packing performance predictions. To validate the hydrodynamic predictions from the CFD simulations, the predicted liquid holdup was compared to experimental liquid holdup data and showed a deviation of six percent. Comparisons of the predicted liquid flow angle and friction factor to analytical expressions further validated the hydrodynamic CFD predictions. The liquid mass transfer coefficient predictions were validated with experimental data, having a deviation of eight percent, as well as with semi-empirical models. A structured packing geometry study was conducted for the liquid-phase performance, and liquid upheaval near packing crimps significantly contributed to the chemical separation.

A novel interfacial mass transfer model was developed for multiphase CFD simulations. This model can handle concentration jumps of multiple orders of magnitude across the gas-liquid interface. An analytical solution to a two-dimensional system validated the CFD predictions, producing an error of less than one percent. The model was adapted for turbulent conditions and was demonstrated on a structured packing system.