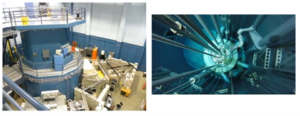

The NETL TRIGA reactor (illustrated in Figure 1) has served as a university research reactor for irradiation experiments, radioisotope production, and operator training since its initial criticality in 1992. Due to its extensive operating history, readily available design and operating data, inherent simplicity and safety, and operational flexibility, the NETL TRIGA makes an excellent candidate for designing and testing DTs. Additionally, developed DTs may assist in TRIGA operations, particularly with regards to reactor startup predictions, achieving and maintaining power level targets, and beam port spectrum tuning. DTs might also provide a means for developing automated digital-twin-based control systems, with said systems ultimately being incorporated within a reactor licensing framework.

Figure 1: NETL Reactor Pedestal / High Bay (left) and Core Pool (right)

Currently, NETL employs a combination of High Fidelity (HiFi) modeling (ex: MCNP) and Reduced Order Modeling (ex: Point Kinetics) modeling for reactor / experiment design and licensing as well as operational control guidance. Though these tools have an establish track record, performance gaps exist which may be improved through more contemporary HiFi-ROM methods which make use of live operational data, as depicted in Figure 2. Additionally, newer HiFi-ROM pipelines may be used as data generators for developing data-intensive operator guidance tools / automated control systems, such as reinforcement-learning-based systems, to assist operators in the performance of routine activities. The primary focus of this effort is the development of novel data / simulation pipelines, demonstration of their ability to provide increased / enhanced information to operators, and explore their potential for improving / automating routine operational activities.

Figure 2: Data / Simulation Pipeline

Task 1: Historic operational data and models will be retrieved and processed for pipeline development. This task will include the development of requisite post-processing infrastructure. This historic reference information may be useful in pipeline development and ROM training / tuning.

Task 2: Access to live or near-live operational data and models along with post-processing infrastructure will be established to help with pipeline development and evaluating the pipeline in a live / near-live operational framework. This may similarly be used for testing / evaluating the performance of automated control schemes / prescriptive operator guidance tools developed from these pipelines.

Task 3: HiFi-ROM pipelines will be setup using data from Tasks 1 and 2. This task will explore various pipeline architectures, evaluating and documenting their performance with regards to simulating the historic and live operating conditions in terms of runtime, computational cost, and accuracy Figures of Merits (FOMs). This task may allow for multiple final simulation pipelines at conclusion, with each being suitable for some subset of TRIGA applications.

Task 4: Operational guidance and / or automated control tools will be developed using the pipelines established in Task 3 and / or using legacy HiFi-ROM approaches. This task will evaluate the performance of these tools by their ability to “help TRIGA operators in the execution of their duties”. This task will also evaluate how said tools may be incorporated into normal TRIGA operations, especially with regards to the TRIGA licensing framework.