The MSTS will serve as a test-bed for the MSRR’s salt flow operations, helping to develop pressure controllers for maintaining system stability, identify the challenges associated with controlling salt flows suspended between cover gases, and assessing the entrainment of the cover gasses into the salt flow and its effect on salt void fraction. Control of this system, with regards to steady-state operations, planned transients, and unanticipated perturbations, may prove difficult and require sophisticated control schemes in order to achieve optimal performance. These may consist of operator directed control schemes, fully automated control schemes, or some combination of the two. Such control schemes can be augmented by Digital Twins (DTs), which can provide on-the-fly guidance to operators and / or provide training data for automated digital controllers. DTs can also help in estimating salt void fraction, which is an important neutronics reactivity feedback characteristic of the MSRR that is difficult to measure directly.

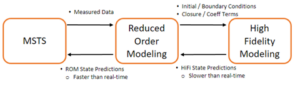

Ideally, High Fidelity (HiFi) first-principles models with very few approximated / tuned parameters would be used as the DTs, but even these types of models encounter practical issues which preclude their general adoption for all tasks. HiFi models are generally computationally expensive, which limits the speed in which simulations may be performed, making them unsuitable for applications requiring faster-than-real-time and / or high-throughput results, such as operational guidance or training for automated controllers. Furthermore, HiFi models typically require state conditions and / or “tuning parameters” for the modeled system that are not directly obtainable from sensor data. These issues may be addressed using Reduced Order Models (ROMs) in a data / simulation pipeline as illustrated in Figure 1. The primary focus of this effort is the development of novel data / simulation pipelines, demonstration of their ability to provide increased / enhanced information to operators, and explore their potential for improving / automating salt flow control.

Figure 2: Data / Simulation Pipeline

Task 1: HiFi MSTS reference models along with requisite post-processing infrastructure will be setup to allow for the generation of synthetic data, which will in turn be used for building the modeling pipelines. This is necessary because actual MSTS measurement data will not be available until after MSTS completion. These reference models will be different from the HiFi models used as part of the pipelines, and will serve as synthetic data generators, in lieu of actual physical measurements.

Task 2: HiFi-ROM pipelines will be setup using data generated from the Task 1 HiFi MSTS reference models. This task will explore various pipeline architectures, evaluating and documenting their performance with regards to simulating the progression problems in terms of runtime, computational cost, and accuracy Figures of Merits (FOMs).

Task 3: Operational guidance and / or automated control tools will be developed using the pipelines established in Task 2 and / or using legacy HiFi-ROM approaches. This task will evaluate the performance of these tools by their ability to predict salt conditions (i.e., void fraction) and help in maintaining operational targets. This task will also evaluate how said tools may be incorporated into normal MSRR operations, especially with regards to the MSRR licensing framework.

Task 4: HiFi-ROM pipelines will be adapted to the real MSTS once it becomes operational, using actual operating data and providing feedback to the MSTS operators. Access to live or near-live operational data along with post-processing infrastructure and operations feedback infrastructure will be established as part of this task.