Molten salt reactors utilize a cover-gas: over the salt in the pump, above the experimental tank, and in the drain tank. This cover-gas ensures a predictable operating pressure and enables pressure differentials to move fluid between the drain tank and reactor core. In addition, one means of removing fission gases is to bubble an inert gas (He) through the salt to extract the gas particles in the fluid. Both the bubbler and gas-salt interfaces present an avenue for gas bubbles to become entrained in the fuel salt; fission gas generation can also contribute in a commercial MSR. If the void fraction in the salt becomes too high, it presents several risks for efficient operation, including reactivity control and multiphysics instabilities. Therefore, there is a need to develop an integrated approach to enable the design and validation of a structure (e.g. baffle) that will efficiently extract bubbles from a flowing salt during all operating conditions. The quality of the baffle design, at least initially, is insignificant; the focus is on developing an approach to enable design and validation.

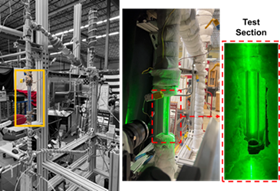

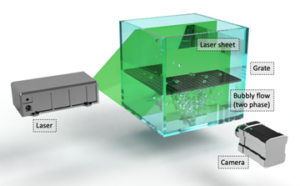

There is an existing flow loop at Texas A&M University that consists of a pump, bubble injector, and window to enable Particle Image Velicometry (PIV) to track individual bubbles flowing in a vertical section of the piping (Figure 1). At the end of window there is a separator that allows many of the air bubbles to escape the experiment while the salt, and some bubbles remain entrained. This will be modified to allow for a window and PIV system to monitor the bubbles in the separator (Figure 2) and on the return loop and enhanced with digital controls. This will create a system that will: pump flowing salt through a loop at digitally controlled various speeds, inject bubbles into the salt at various digitally controlled flow rates, provide a digitally-controlled heater to adjust the isothermal experiment temperature, include a baffle section that is designed to remove most or all of the bubbles, and showcase parameters that are designed to enable continuous measurement of the bubble distributions at key locations in the flow loop such as prior to entering the baffle, within the baffle, and after leaving the baffle.

Figure 1: Existing experiment at Texas A&M for Particle Image

Velicometry (PIV) of vertically flowing bubbles in a liquid salt

Figure 2: PIV of a bubble extraction grate for the new experiment

Task 1: A computer adjacent to the experiment will have a data acquisition system that continuously stores all data, processes particle image velocimetry (PIV) data to produce engineering data, maintains statistics on the experimental and engineering data, and has controls to enable a user to adjust the pump speed, bubble injection rate, and heater power, maintain statistics on the experimental and engineering data to provide quantified experimental uncertainties.

Task 2: The processed data will be regularly transferred to Texas Advanced Computing Center (TACC) for high-fidelity analysis of experimental data on the LoneStar6 supercomputer. The CFD model of the flow loop will be developed and made usable on TACC and the accuracy of the two-phase flow parameters in the CFD model will be evaluated and calibrated using weekly data transfers and historical results.

Task 3: A suite of test problems will be developed that will replicate thousands of transient experiments. The results from the suite of test cases using the high-resolution, calibrated multiphase CFD models will be used to generate simplified physics models with a quantified range of uncertainties. These test cases will be designed to reflect a wide range of experimental operating conditions for transient and steady-state problems and the CFD will provide high-resolution estimate of the two-phase flow. As experimental data is acquired (Task 2) and the CFD models improve, the CFD model (and set of training cases) will enable a regular update of the reduced-order model throughout the project.

Task 4: The reduced-order model will be transferred back to the local workstation (and regularly updated) for use with the experiment. As the experiment continues to operate, in a variety of time-dependent flow, bubble, temperature states, the data gathered in the data acquisition system will be used to continually calibrate the reduced-order model of the bubble extraction device, within the computed uncertainty from Task 4, to improve the predictive capability of the reduced-order model during operation.

Task 5: With a functioning reduced-order model, with quantified uncertainties in all parameters, the software can be used to identify additional experiments that should be run, which will provide the highest value of new data to minimize the error in the reduced-order model. With an accurate CFD model, a new baffle can be designed with predictable results.